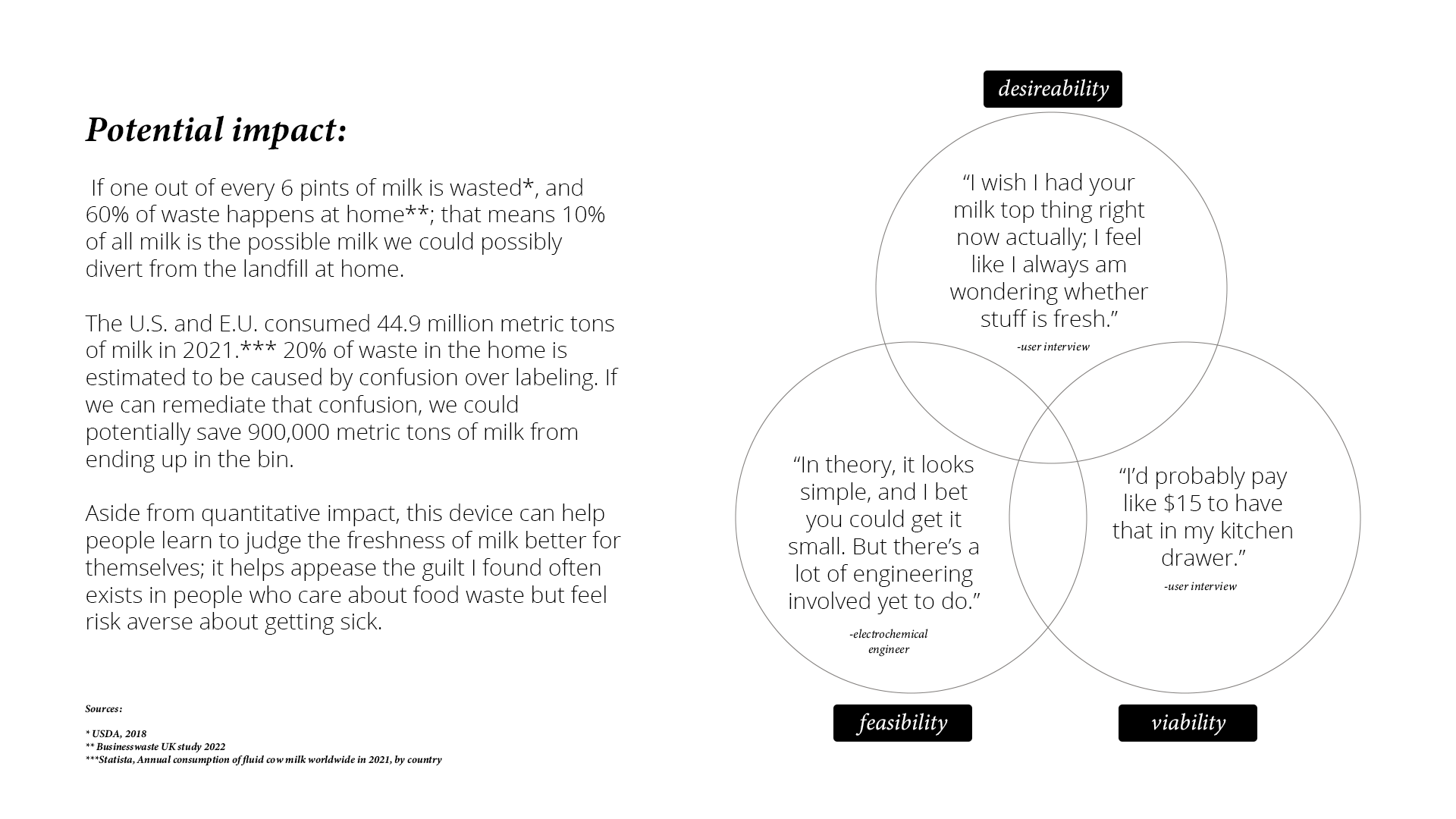

Up to 60% of people worry that the food they’ll eat will harm them at some point in the next two years. Whether or not it ends up being true, this fear results in risk avoidant behaviour like discarding anything that might be bad. Unfortunately, current methods of tracking freshness, like expiration dates and best-by dates, may actually make things worse, with an estimated 20% of waste in the home caused by confusion over labelling.

What if there was an easy-to-use, science-backed way to tell for sure whether something is fresh or not?

Well, there is.

For years, scientists have been able to map key indicators like pH or volatile organic compound emissions to bacterial count in food.

The problem? These tests are designed for a laboratory setting, and can be finicky to operate – certainly not something you want to do each time you open the fridge to get some milk.

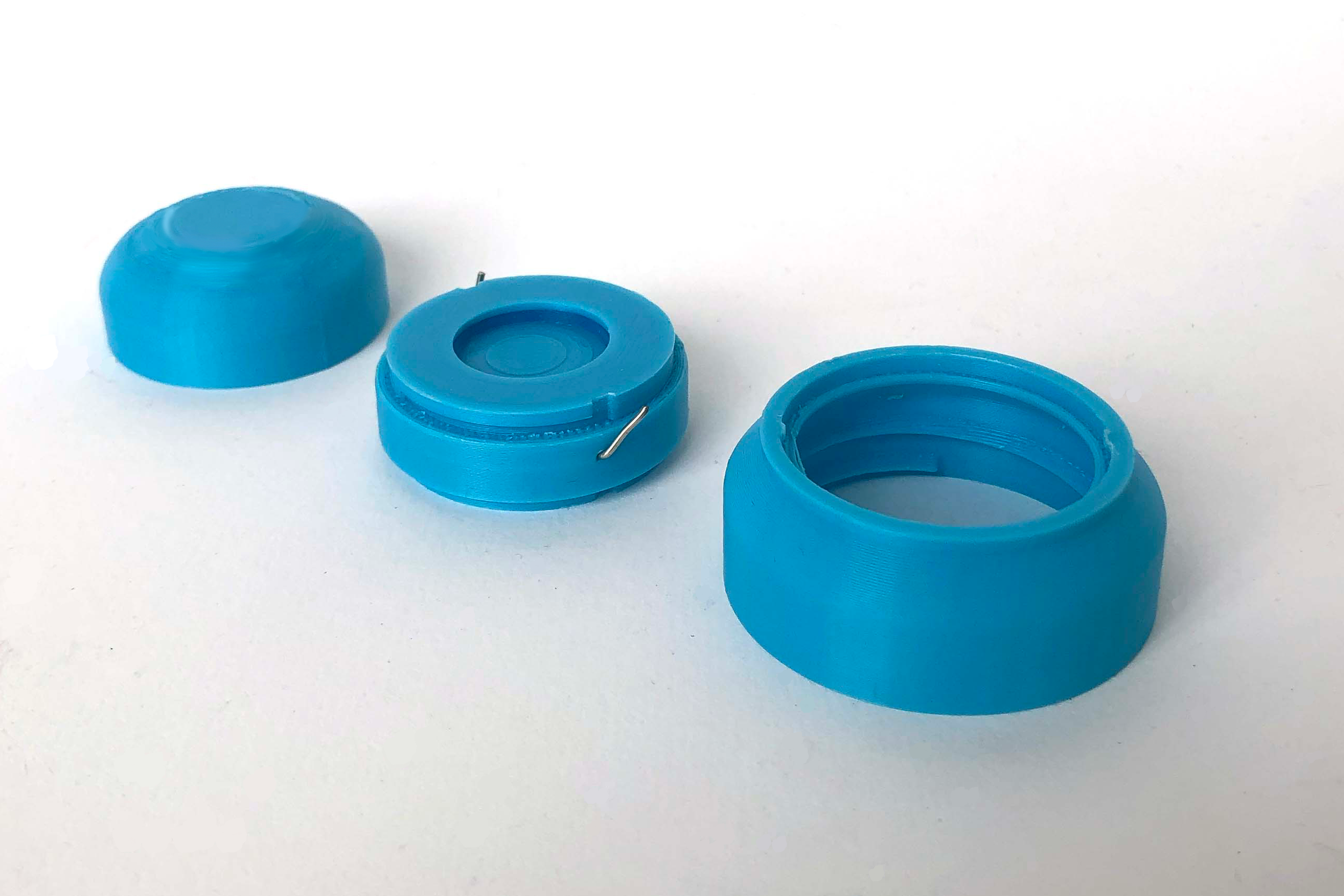

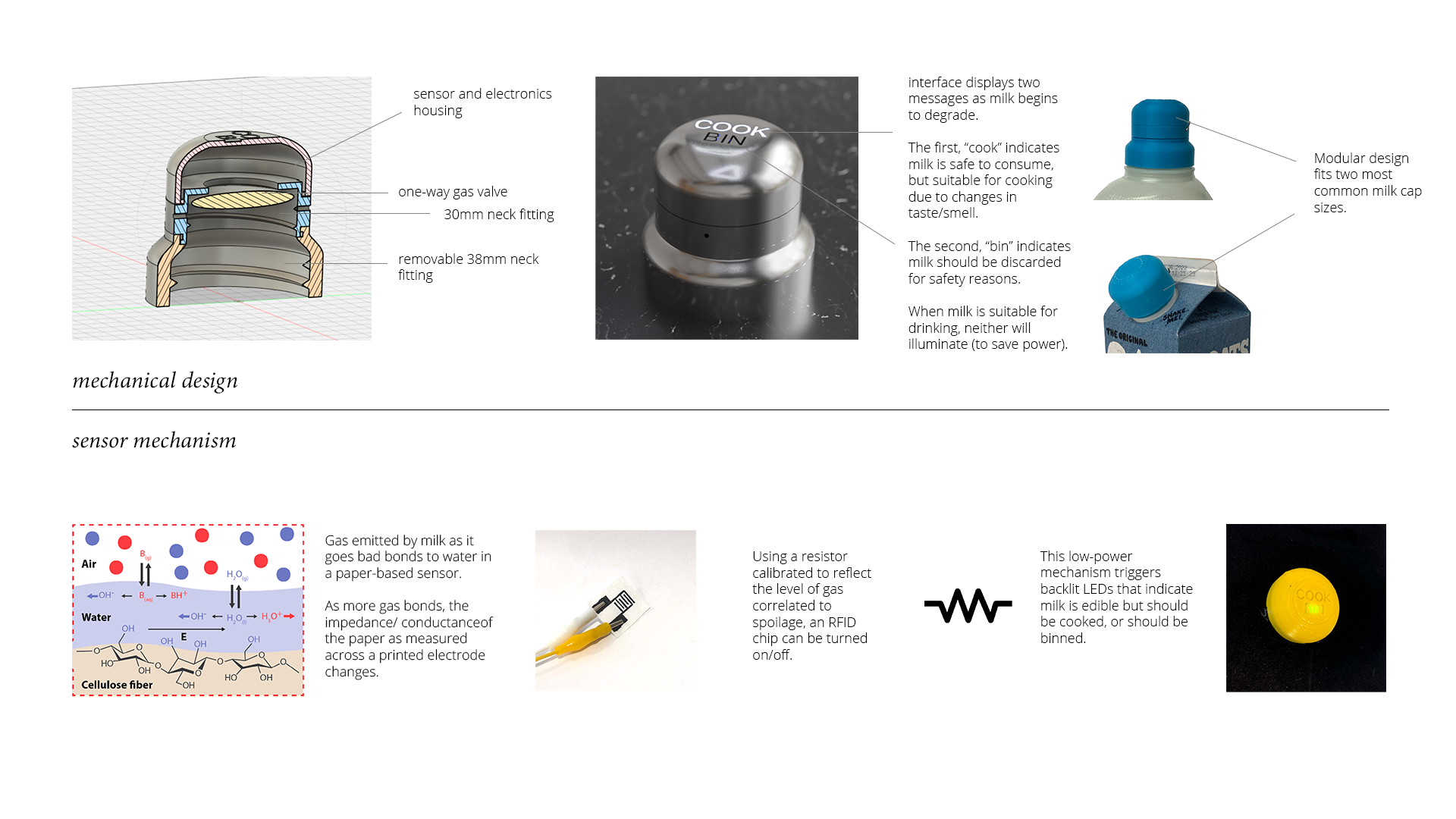

Enter Knose, a re-usable, consumer-friendly freshness sensor that integrates seamlessly with off-the-shelf packaging. Think of it like your meat thermometer – but for food freshness.

problem definition

This project started with a big problem: global food waste. Food waste contributes to greenhouse gases, and overproduction of food to compensate for waste puts additional strain on agricultural systems. That’s in part why project drawdown ranks reducing food waste as the #1 most impactful solution in combatting climate change.

Within this big problem are a host of smaller friction points. One such point is food freshness and labeling – much food gets thrown out because of confusion or uncertainty about safety. I began with a question: “How might we design a packaging/storage system that helps reduce food waste by better communicating freshness/safety?

user research

Through user research and expert interviews, I narrowed to a specific use case and insight to tackle:

Insight: people still discard milk that passes the “sniff test” if it’s past its expiration date because they just aren’t sure.

So, how might we provide an at-home test that’s more precise than the “sniff test”?

Why milk? Milk is large product category (EU and US shoppers consumed 44.9 million metric tons in 2021) and an estimated ⅙ of all product is currently wasted.

Taking the longer view, this project has the potential to expand into new product categories and formats of equal concern for consumers - such as alternative milks, meat, fish, and eventually also bread.

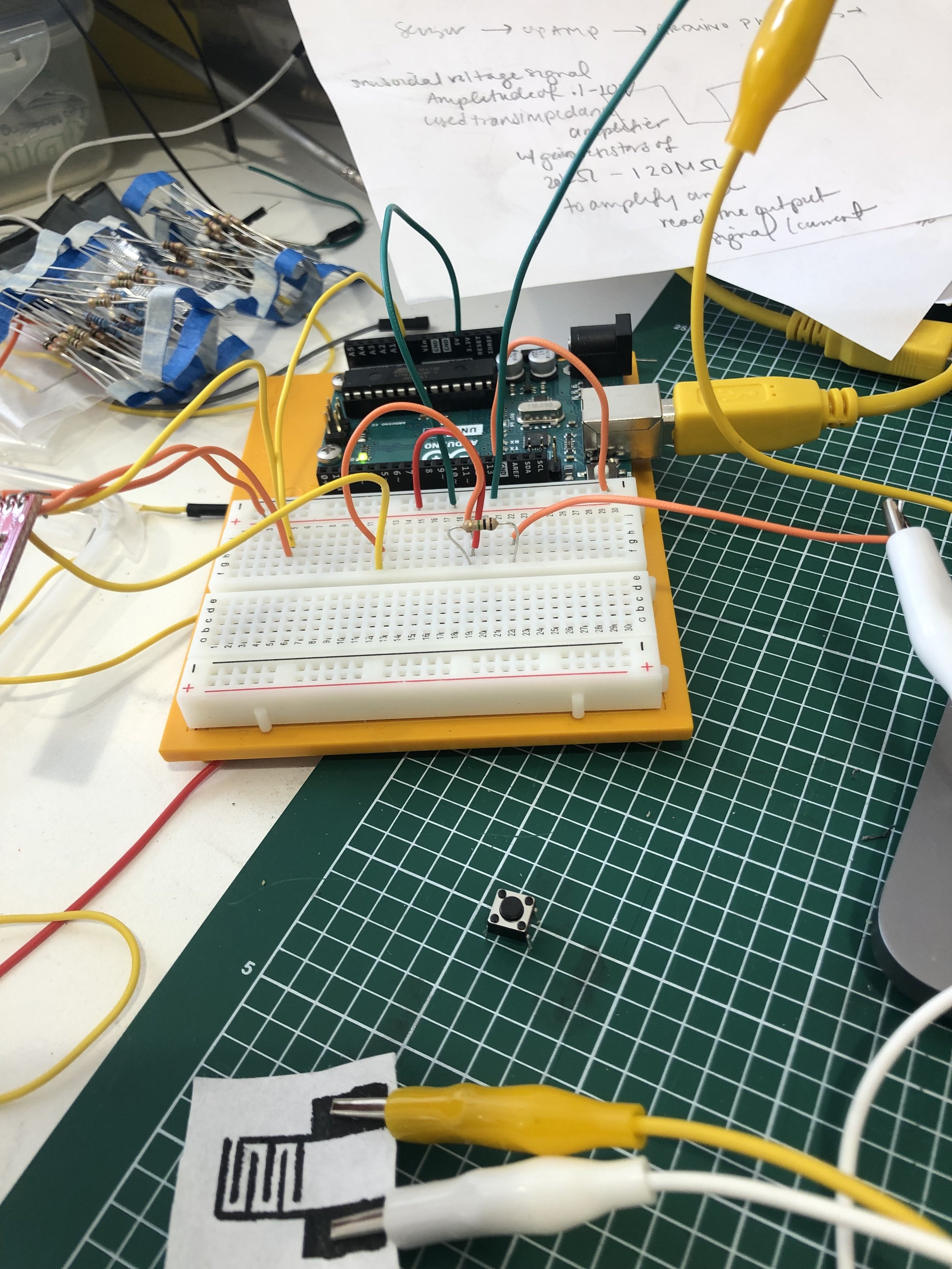

sensor technology research and prototyping

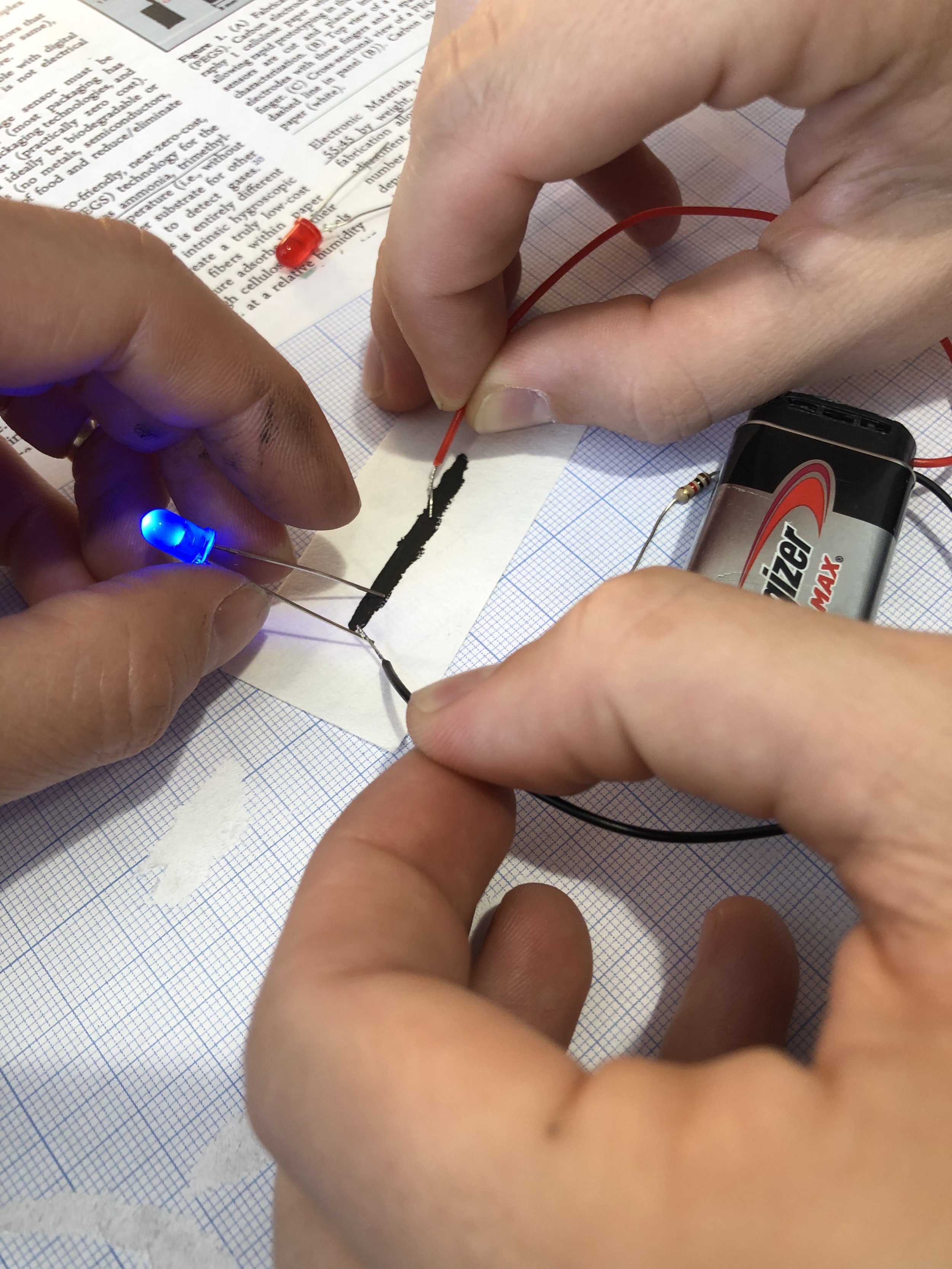

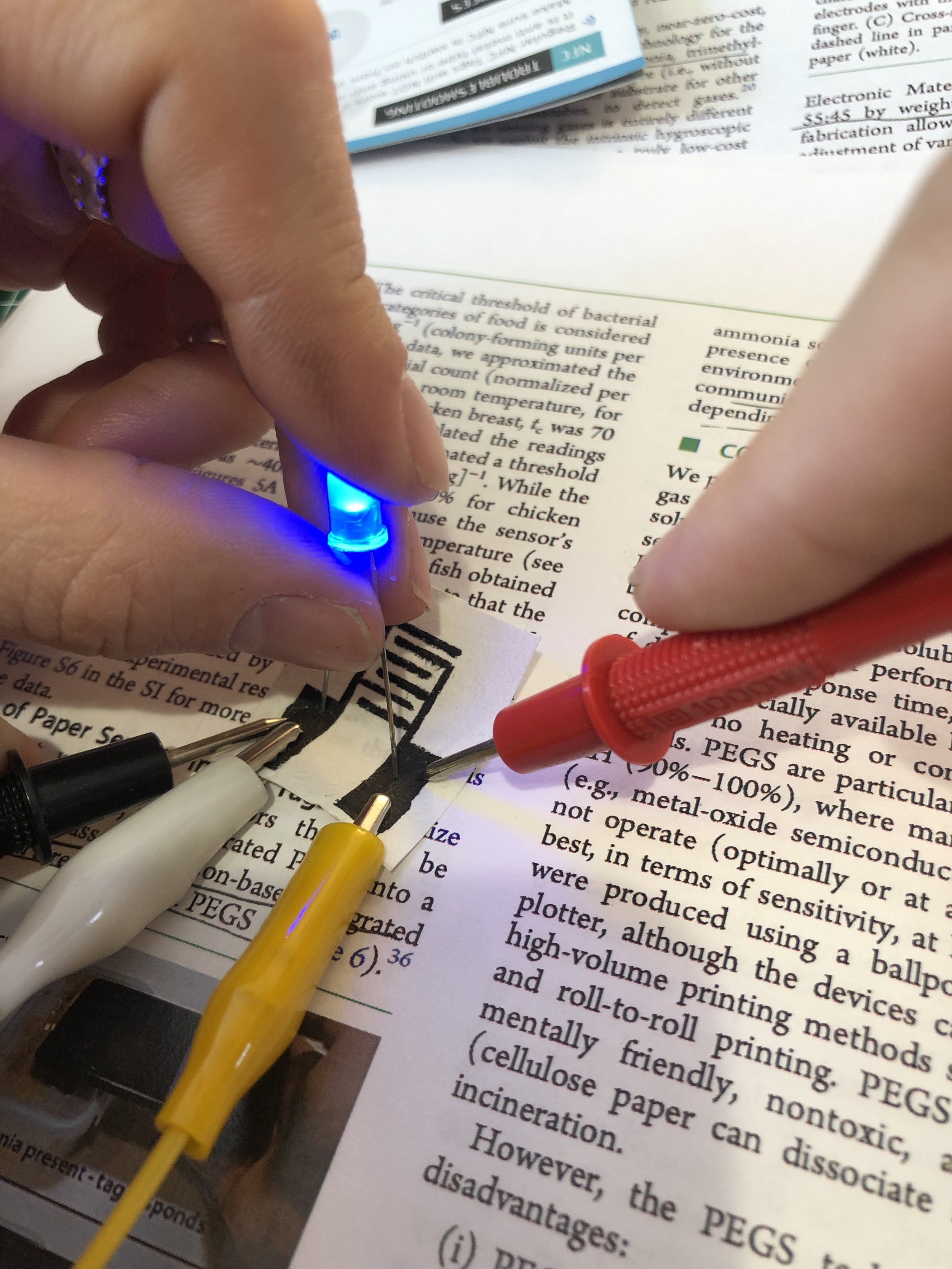

After user research led me to a format and idea (a reusable cap that tells you how fresh your milk is), I started experimenting with the type of sensing mechanism that might fit within a milk cap, and also exploring how to physically construct a cap that would fit on a majority of commercially available milk cartons.

The large majority of food freshness indicators in development don’t directly quantify the spoilage status of food. Instead, they work by tracking correlational factors like time, exposure to oxygen, or elevated temperatures. They do this because the technology is cheaper. However, uptake is still low because even these low fidelity trackers add time and money to packaging lines.

My research pointed to a different opportunity area – the home – and a different pain point – being certain food is safe. As such, my design scope focused on technology that directly measures food spoilage in a format that could be reversible (or re-usable), even if it costs more to produce initially.

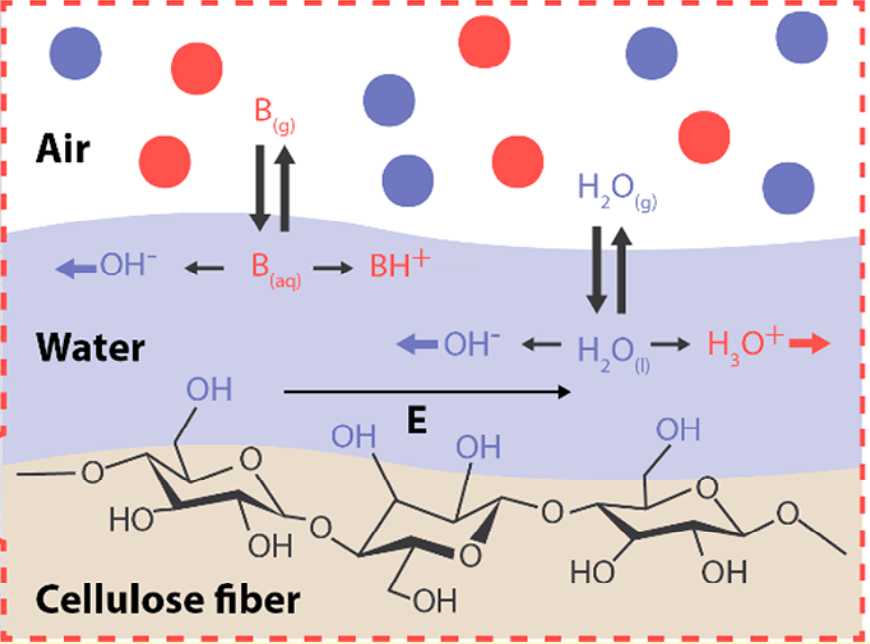

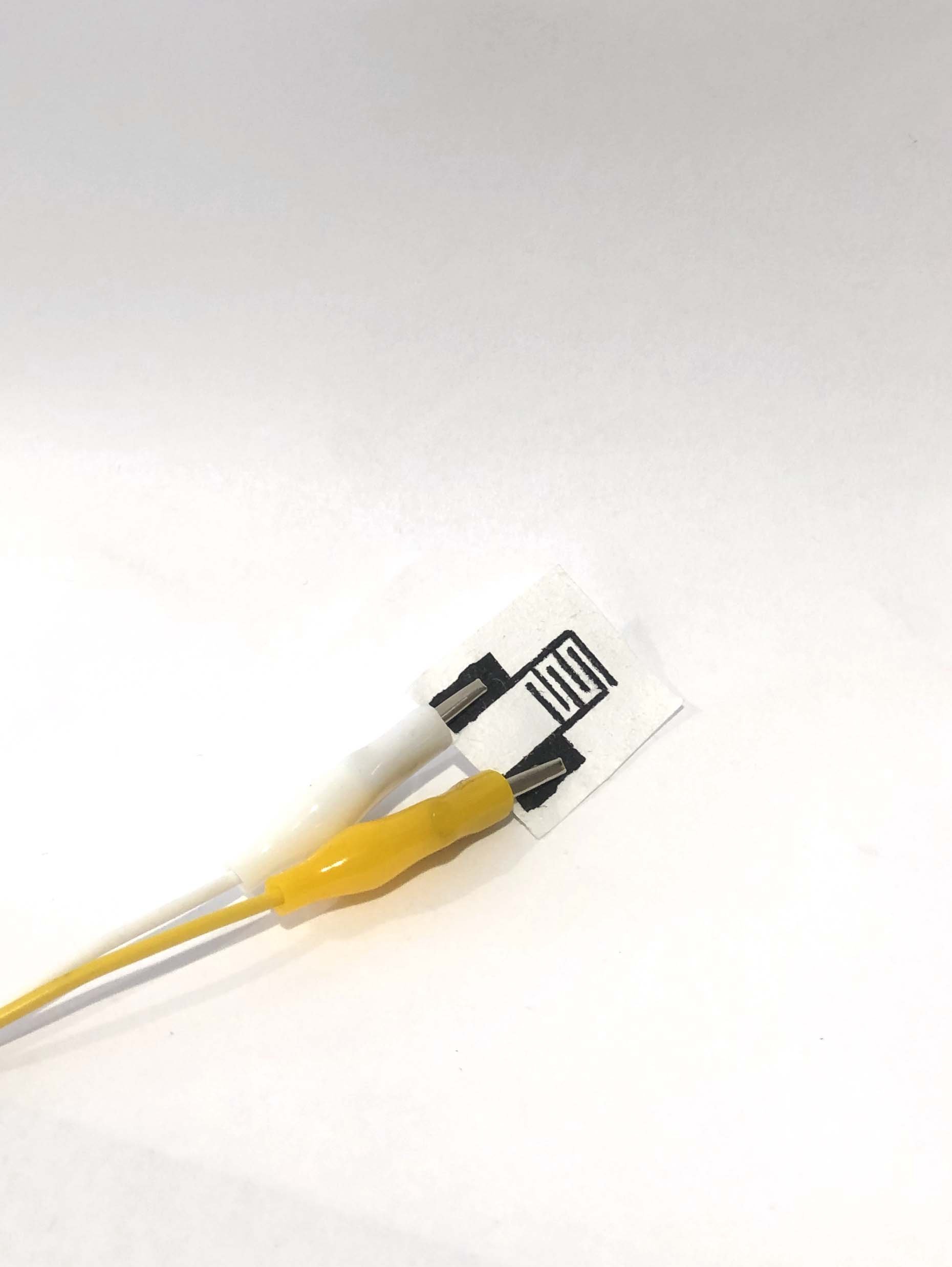

As food spoils, chemical changes occur that can be sensed generally by three main methods: 1) measuring changes in pH of food, 2) measuring volatile organic compounds (gases) given off by food, and 3) directly measuring bacterial count within food. Method 3 can be time-intensive and require culturing samples. pH often requires direct contact with food. After reviewing the existing scientific literature, I decided to concentrate on VOC-sensing technology, and specifically identified a paper-based electronic gas sensor as a methodology to exploit for v 1.0 of the Knose cap system.

final design and evaluation

Research credit:

Cellulose Fibers Enable Near-Zero-Cost Electrical Sensing of Water-Soluble Gases

Giandrin Barandun, Matteo Soprani, Sina Naficy, Max Grell, Michael Kasimatis, Kwan Lun Chiu, Andrea Ponzoni, and Firat Güder

ACS Sensors 2019 4 (6), 1662-1669

DOI: 10.1021/acssensors.9b00555