Flow State

This project explores easier biomaterial 3D printing with vibration-based liquefaction, and proposes a new type of extruder head for 3D printers that leverages a 40kHz ultrasonic transducer to allow for easier extrusion of thick and textured materials.

3D printing with biomaterials is an exciting technique for upcycling and remanufacturing waste streams into new forms, but is currently extremely challenging due to the texture and other physical properties of these materials. Without binder additives and laborious pre-processing, materials can clog 3D printer nozzles or slump once deposited. This project explores using ultrasonic vibration to temporarily reduce the viscosity of materials at the point of extrusion, opening up opportunities to print with a wider range of materials.

This project was inspired by a group of artists and designers at University of Birmingham's STEAMhouse who were exploring the use of new biomaterials within their practice. The machinery they use is conventionally applied to 3D printed ceramics – and I witnessed first hand how challenging it can be to develop a new material that can be effectively workable with the existing machinery. This inspired me to try to innovate the process of extrusion to accommodate a broader range of materials.

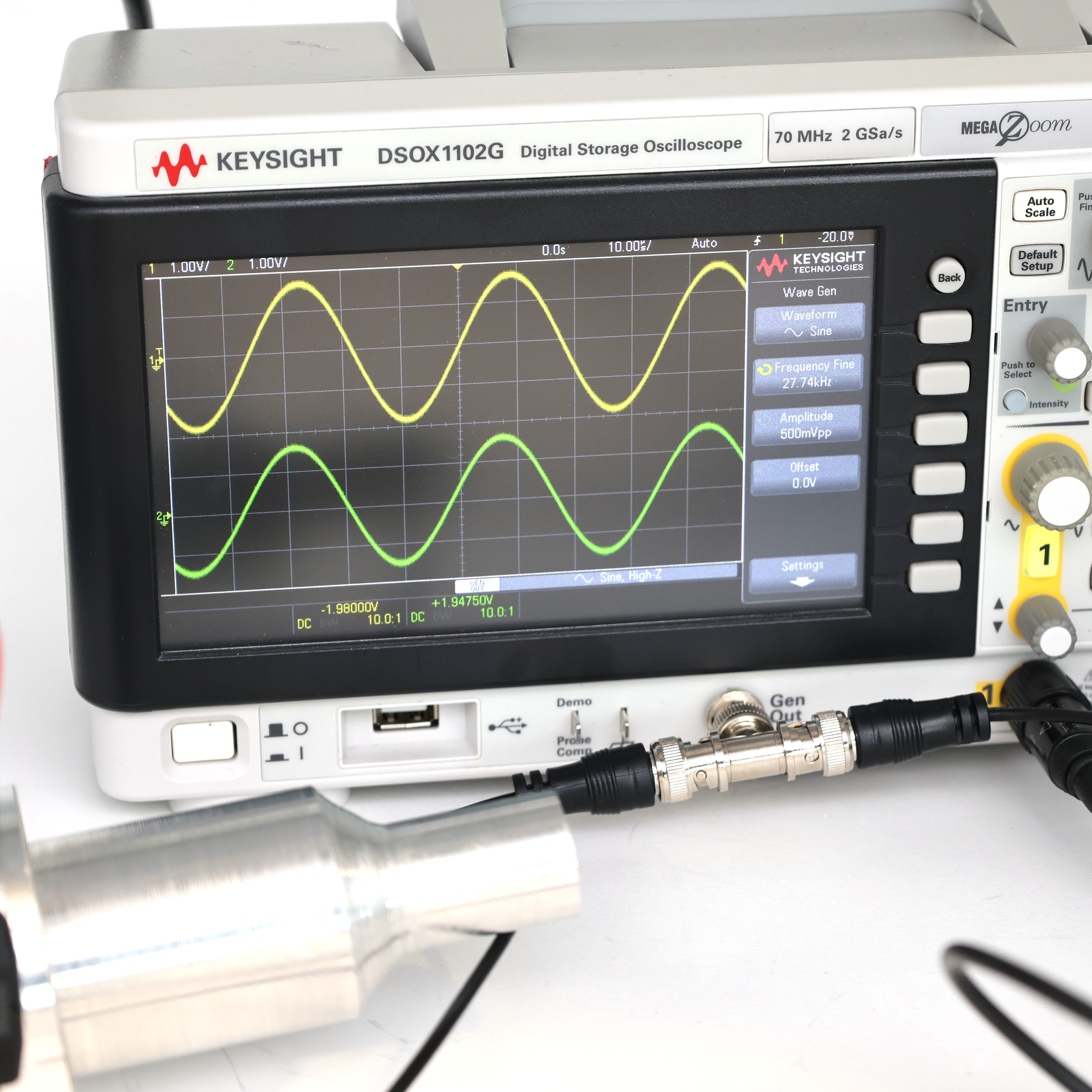

Ultrasonic vibration can temporarily reduce the viscosity of materials and cause them to behave in more "liquid-like" ways, because of an effect called cavitation. My project tested use of ultrasonic transducers and corresponding amplifiers to see if this effect could improve printing of common bio-based materials by improving their flow and reducing nozzle clogs.